|

|

|

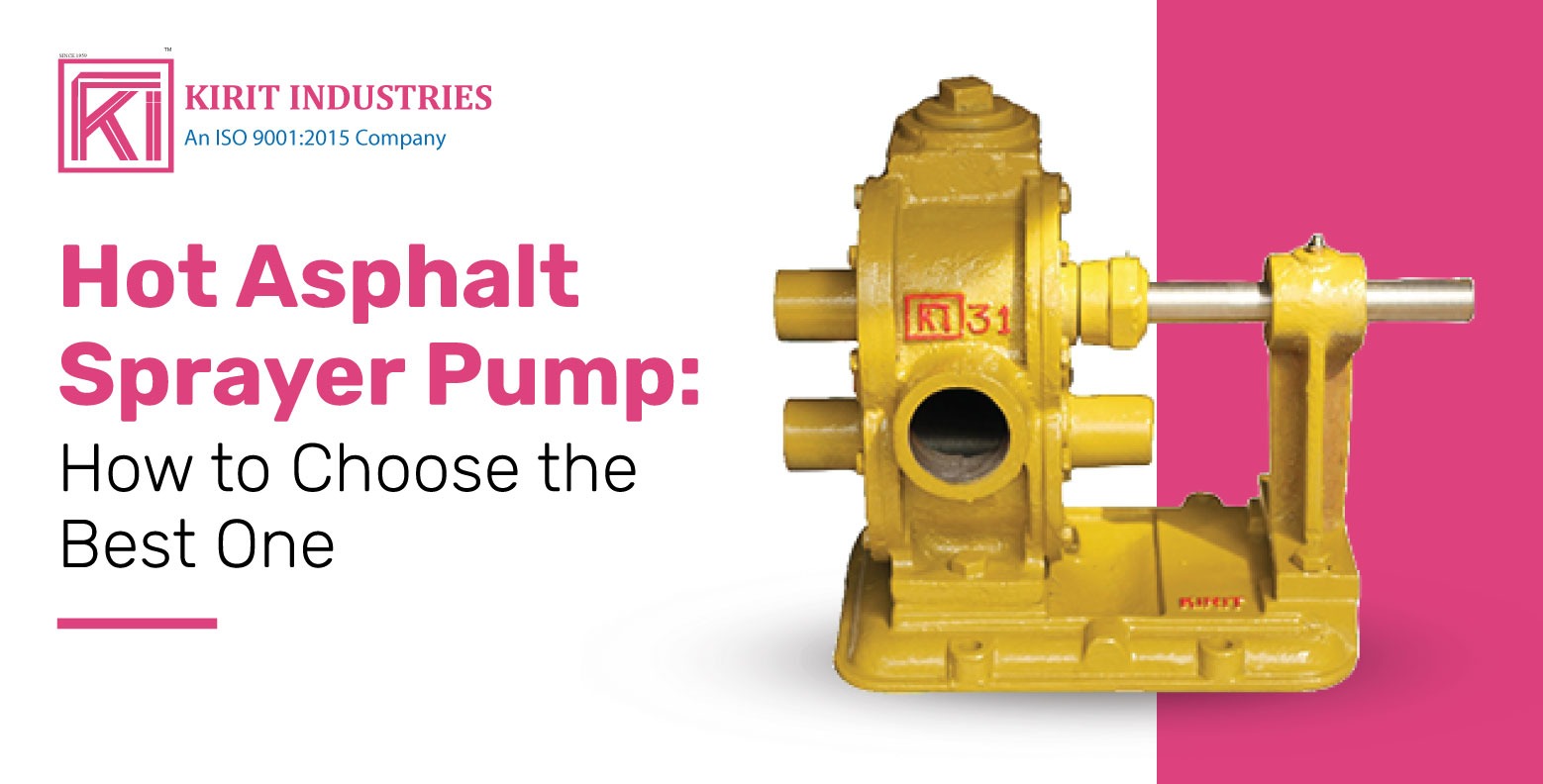

Hot Asphalt Sprayer Pump: How to Choose the Best One

It is in road construction, maintenance, and pavement that the right hot asphalt sprayer pump makes or breaks the smoothness and success of the operation. You may be a contractor, engineer, or project manager, whichever you are buying the right pump yourself because it ensures proper spraying of asphalt, lower downtime, and longer equipment life.

In this guide, we’ll explore what a hot asphalt sprayer pump is, why it's important, and—most critically—how to choose the best one for your specific application.

What Is a Hot Asphalt Sprayer Pump?

Hot asphalt sprayer pump is an important component utilized in the asphalt or bitumen spraying equipment. Pumps possess abrasion and rough heat resistance strength. Pumps deliver level, smooth, and steady flow of hot asphalt during road construction, repair, and maintenance operations.

Whether truck-mounted or stationary, the most important function of the pump is to create a uniform spray that does not clog and loses pressure regardless of temperature.

Why Proper Pump Selection is Important ?

Good asphalt sprayer pump selection is not only how it works—it's purpose, value-price, and safety. Those are the reasons why good one is essential:

Maximum Use of Materials:

Minimum wastage due to better control of sprays.

-

Improved Surface Finish: Avoids patchy asphalt spray.

-

Less Breakdown: Less wear and heat fatigue for long-lived pumps.

-

Fewer Servicings: Fewer servicings, long-lived pumps.

-

Operator Safety: Avoids risk of leaks or pressure surges.

Major Concerns while Choosing a Hot Asphalt Sprayer Pump :

1. Heat Resistance

Hot asphalt would be 150°C (302°F). You need heat-resistance pump with no loss of efficiency or deformation. Pumps need to be made of heat-resistance material, e.g., cast iron, quality steel, or internally coated material.

2. Build and Quality of the Material

Quality of the material has direct correlation with lifespan. See that pumps have:

- High abrasion resistance

- Corrosion protection

- Heat-treated parts

All these attributes offer uniform long-term performance, especially in adverse conditions.

3. Flow Rate and Pressure Capability

Various applications require various flow rates. For instance:

- Patch work requires low flow rate.

- road building is about high-volume output.

Check:

- Gallons per minute (GPM) capacity

- PSI pressure rating (pounds per square inch)

Make sure your pump is suitable to your spraying operation and to your nozzle installation.

4. Type of Pump

There are several types of various hot asphalt pumps:

Gear Pumps – cost-effective, abrasion-proof, ideal for high-viscosity material.

Centrifugal Pumps – least suitable use with hot, sticky asphalt; most suitable use with low viscosity.

Piston Pumps – excellent pressure management but diabolically complex.

Gear pumps are most popular pump used on hot asphalt sprayer pumps due to heat resistance, high-viscosity consistency.

5. Spray System Compatability

Ensure your pump is compatabile with:

- Tank and heating system

- Hoses and nozzles

- Control panels and protection devices

Incompatabile pumps = leaks, cloggings, or poor spray pattern.

6. Ease of Maintenance

The pump must be easy to repair and maintain. Look for:

- Serviceable parts or service kits

- Self-lubricating parts

- Easy to disassemble to repair

- Low-maintenance designs cost themselves out in the long term and time.

- Pick a Quality Maker

When buying, purchase only a quality hot asphalt sprayer pump manufacturer with a sound service and quality image.

Why Kirit Pumps?

Kirit Pumps is a high-end hot asphalt sprayer pump manufacturer. They specialize in:

- High-temperature pumps

- Custom designs to match specific road work projects

- Rethinking long life under severe Indian and international conditions

- Super-class after-sales service and support

With experience spanning years in the trade and with an inclination towards innovation, Kirit Pumps delivers performance and reliability commercial contractors can trust.

Mistakes to avoid :

- Choosing a pump not specially designed for hot asphalt

- Following flow/pressure requirements beyond parameters

- Postponing maintenance due to substandard product design

- Operating low-grade, low-brand equipment

Final Thought

The proper hot asphalt sprayer pump is not a decision to be made hastily because it can create or ruin your business for road maintenance or asphalt paving. With a proper pump, productivity is maximized, equipment life extended, and a better quality finish per job.

Having issues? Let a professional manufacturer like Kirit Pumps, which understands the special needs of asphalt contractors, provide a solution that suits your best needs. Need some advice in choosing the most effective pump? Contact Kirit Pumps today for expert advice on the best hot asphalt sprayer pump to apply on your next job.