|

|

|

|

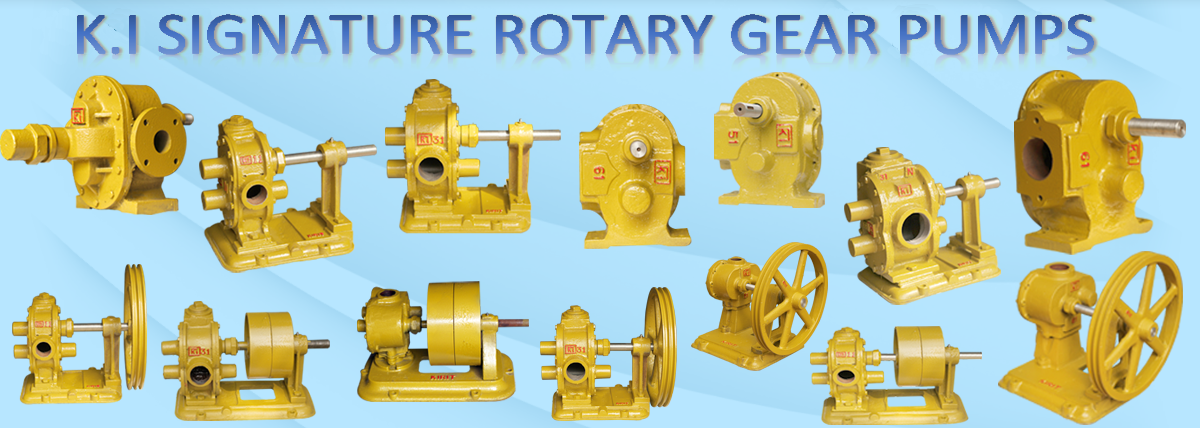

Rotary Gear Pump Manufacturer

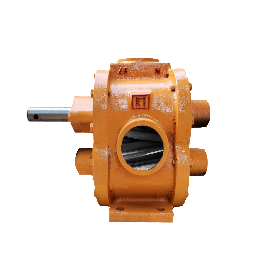

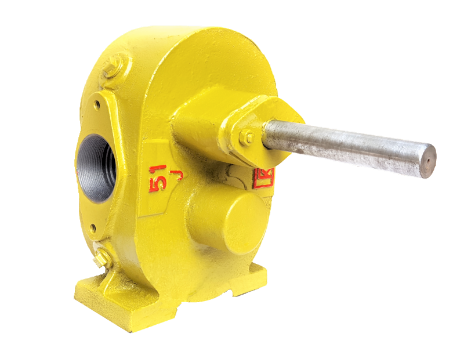

Kirit Industries is a leading Rotary Gear Pump Manufacturer, offering high-quality and high-performance pumps for high-viscous and semi-viscous demanding applications.

The K.I Signature cast iron Series Rotary Lobe Gear Pumps are specially designed for high-viscous liquids which are efficient enough to replace Lobe pumps and gear pumps of other companies. The pump features a close grain cast iron body, covers & large cavity gears. The pump consists of two gears having a large cavity, with precisely cut tooth profiles. These pumps can handle all types of high-viscous liquids without any trouble. These gear pumps can easily handle grease ,Tar, Bitumen, Asphalts, Wax, Soaps, etc. and are also available with jacketed

Working Principle of Rotary Gear Pump

The positive displacement principle is used by external rotary gear pumps. K.I Signature pumps come with 2-piece and 3-piece simple designs. The pump has a precisely machined casing and two gears. The idler gear spins as the rotor gear turns, aligning the teeth and drawing fluid in. The space between these gears and their meshing action helps move the fluid effectively.

What Uses and Fluids Are Rotary Gear Pumps Appropriate For?

These pumps are ideal for high-viscous fluids like Grease, fats, syrups, cocoa, resins, bitumen, tar, LDO, furnace oil, castor oil, vegetable oils, chemicals, molasses, paints, silicate of soda, starch, glue, honey, chocolate, glycerin, and more. Applications include hot mix plants, tanker loading/unloading, bitumen sprayers, road paver machines, sugar mills, glue plants, chemical and textile industries, etc. The K.I signature rotary gear pump is widely used in road truck tankers through PTO drive with their engine.

With an ability to handle fluids with 250,000 SSU viscosity @ 10Kg/cm², these pumps deliver unmatched performance for high-viscosity transfer.

Material Used for Manufacturing Rotary Gear Pump

The growing demand for "K.I" items reflects their trusted performance. Many clients return for repeat orders, confident in the reliability and efficiency of our pumps. This reputation has made Kirit Industries a preferred brand.

Kirit Industries is the first company in India to introduce a special three-port design and a hybrid design of rotary and lobe pumps. This models used in Road Tanker or Fighter Rotary Gear Pump, which can be easily mounted on tankers, trucks, tractors, or any mobile vehicle and powered by their engine PTO. Available in sizes from 1½” to 3”, these pumps offer a flow capacity of up to 59.4 m³/h (59,400 LPH), with multiple mounting options like side suction-side delivery, bottom suction-top delivery, and side suction-top delivery.

Why Choose Kirit Industries signature Rotary Lobe Pump over other Manufacturers?

As trusted Rotary Gear Pump Manufacturers, Kirit Industries delivers durable, cost-efficient, and high-quality solutions. We’re also a trusted source for rotary gear lobe pump. Our pumps are widely used in processing plants, chemical facilities and various industries where high-viscous and semi-viscous liquids are part of the operation.

With strong construction, remarkable suction capacity, and effective displacement design, our pumps meet market demands with premium quality and competitive pricing.

Connect with Kirit Industries today for the best and most cost-efficient rotary gear pumps, K.I signature rotary gear lobe pumps.

Application:-

- Loading / Unloading / Transferring of Bitumen, Molasses

- Vegetable Oils, Viscous Oils, Chemicals, Grease, Tallow

- Colour & Paints, Soaps, Silicate of Soda, Starch, Glue

- Honey, Chocolate, Glycerin, Acids, Ammonia, Asphalt

- Boiler Compounds, Condiments, Dairy Products, Dyes

- Food Products, Fruit Juices, Gasoline, Kerosene, Ink

- Spray Mixtures, Slurry Waste, and More

| Part | Material |

|---|---|

| Pumps series | SSV11 |

| Pump body | Cast Iron |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Gears | Cast iron Spur gears |

| Shaft | Steel |

| Shaft Seal | Oil seal or gland thread |

| Shaft | Steel |

| Gland | Cast iron |

| Max operating temp. | 200 °C |

| Base plate | Cast iron |

| Pedestal | Cast iron |

| Pulley | Cast iron 15” |

| Key | En-8 |

| Dowel pin | En-8 |

| Hex bolts | Steel |

| Lit/min@ 400 RPM | 181.6 |

| operating RPM | 100 to 400 |

| 3 port | 1.5” |

| Working pressure | Upto 10 kgs/cm2 |

| Part | Material |

|---|---|

| Pumps series | SS 15 |

| Pump body | Cast Iron |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Gears | Cast iron helical gears |

| Shaft | Steel |

| Shaft Seal | Viton Oil seal |

| Gland | Cast iron |

| Max operating temp. | 300 °C |

| Base plate | N/A |

| Pedestal | N/A |

| Pulley | N/A |

| Key | En-8 |

| Dowel pin | En-8 |

| Hex bolts | Steel |

| Lit/min@ 400 RPM | 194.85 |

| operating RPM | 100 to 700 |

| 3 port | 2” |

| Working pressure | Upto 10 kgs/cm2 |

| Part | Material |

|---|---|

| Pumps series | SSLF11 |

| Pump body | Cast Iron |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Gears | Cast iron Spur gears |

| Shaft | Steel |

| Shaft Seal | Oil seal or gland thread |

| Gland | Cast iron |

| Max operating temp. | 200 °C |

| Base plate | Cast iron |

| Pedestal | Cast iron |

| Pulley | N/A |

| Key | En-8 |

| Hex bolts | Steel |

| Lit/min@ 400 RPM | 181.6 |

| operating RPM | 100 to 400 |

| 3 port | 1.5” |

| Working pressure | Upto 10 kgs/cm2 |

| Part | Material |

|---|---|

| Pumps series | SS11 |

| Pump body | Cast Iron |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Gears | Cast iron Spur gears |

| Shaft | Steel |

| Shaft Seal | Oil seal or gland thread |

| Gland | Cast iron |

| Max operating temp. | 200 °C |

| Base plate | Cast iron |

| Pedestal | Cast iron |

| Pulley | Cast iron 15” |

| Key | En-8 |

| Hex bolts | Steel |

| Lit/min@ 400 RPM | 181.6 |

| operating RPM | 100 to 400 |

| 3 port | 1.5” |

| Working pressure | Upto 10 kgs/cm2 |

| Part | Material |

|---|---|

| Pumps series | SSV31 |

| Pump body | Cast Iron |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Gears | Cast iron Spur gears |

| Shaft | Steel |

| Shaft Seal | Oil seal or gland thread |

| Gland | Cast iron |

| Max operating temp. | 200 °C |

| Base plate | Cast iron |

| Pedestal | Cast iron |

| Pulley | Cast iron 15” |

| Key | En-8 |

| Hex bolts | Steel |

| Lit/min@ 400 RPM | 254 |

| operating RPM | 100 to 400 |

| 3 port | 2” |

| Working pressure | Upto 10 kgs/cm2 |

| Part | Material |

|---|---|

| Pumps series | SSLF31 |

| Pump body | Cast Iron |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Gears | Cast iron Spur gears |

| Shaft | Steel |

| Shaft Seal | Oil seal or gland thread |

| Gland | Cast iron |

| Max operating temp. | 200 °C |

| Base plate | Cast iron |

| Pedestal | Cast iron |

| Pulley | N/A |

| Key | En-8 |

| Hex bolts | Steel |

| Lit/min@ 400 RPM | 254 |

| operating RPM | 100 to 400 |

| 3 port | 2” |

| Working pressure | Upto 10 kgs/cm2 |

| Part | Material |

|---|---|

| Pumps series | SS31 |

| Pump body | Cast Iron |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Gears | Cast iron Spur gears |

| Shaft | Steel |

| Shaft Seal | Oil seal or gland thread |

| Gland | Cast iron |

| Max operating temp. | 200 °C |

| Base plate | Cast iron |

| Pedestal | Cast iron |

| Pulley | Cast iron 15” |

| Key | En-8 |

| Hex bolts | Steel |

| Lit/min@ 400 RPM | 254 |

| operating RPM | 100 to 400 |

| 3 port | 2” |

| Working pressure | Upto 10 kgs/cm2 |

| Part | Material |

|---|---|

| Pumps series | SSV31N |

| Pump body | Cast Iron |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Gears | Cast iron Spur gears |

| Shaft | Steel |

| Shaft Seal | Oil seal or gland thread |

| Gland | Cast iron |

| Max operating temp. | 200 °C |

| Base plate | Cast iron |

| Pedestal | Cast iron |

| Pulley | Cast iron 15” |

| Key | En-8 |

| Hex bolts | Steel |

| Lit/min@ 400 RPM | 320 |

| operating RPM | 100 to 400 |

| 3 port | 2.5” |

| Working pressure | Upto 10 kgs/cm2 |

| Part | Material |

|---|---|

| Pumps series | SS31N |

| Pump body | Cast Iron |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Gears | Cast iron Spur gears |

| Shaft | Steel |

| Shaft Seal | Oil seal or gland thread |

| Gland | Cast iron |

| Max operating temp. | 200 °C |

| Base plate | Cast iron |

| Pedestal | Cast iron |

| Pulley | N/A |

| Key | En-8 |

| Hex bolts | Steel |

| Lit/min@ 400 RPM | 320 |

| operating RPM | 100 to 400 |

| 3 port | 2.5” |

| Working pressure | Upto 10 kgs/cm2 |

| Part | Material |

|---|---|

| Pumps series | SS45 |

| Pump body | Cast Iron |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Gears | Helical steel |

| Shaft | Steel |

| Shaft Seal | Oil seal or gland thread |

| Gland | Cast iron |

| Max operating temp. | 200 °C |

| Base plate | N/A |

| Pedestal | N/A |

| Pulley | N/A |

| Key | En-8 |

| Hex bolts | Steel |

| Lit/min@ 900 RPM | 990 |

| operating RPM | 100 to 900 |

| 3 port | 2.5” |

| Working pressure | Upto 10 kgs/cm2 |

| Part | Material |

|---|---|

| Pumps series | STV 51 |

| Pump body | Cast Iron |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Gears | Cast iron Spur gears |

| Shaft | Steel |

| Shaft Seal | Oil seal or gland thread |

| Gland | Cast iron |

| Max operating temp. | 200 °C |

| Base plate | N/A |

| Pedestal with bush | Cast iron with bronze |

| Pulley | Cast iron 15” |

| Key | En-8 |

| Hex bolts | Steel |

| Lit/min@ 400 RPM | 498 |

| operating RPM | 100 to 900 |

| 2 port | 2 |

| Working pressure | Upto 10 kgs/cm2 |

| Part | Material |

|---|---|

| Pumps series | SSLF 51 |

| Pump body | Cast Iron |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Gears | Cast iron Spur gears |

| Shaft | Steel |

| Shaft Seal | Oil seal or gland thread |

| Gland | Cast iron |

| Max operating temp. | 200 °C |

| Base plate | Cast iron |

| Pedestal with bush | Cast iron with bronze |

| Pulley | N/A |

| Key | En-8 |

| Hex bolts | Steel |

| Lit/min@ 400 RPM | 498 |

| operating RPM | 100 to 900 |

| 2 port | 2 |

| Working pressure | Upto 10 kgs/cm2 |

| Part | Material |

|---|---|

| Pumps series | SS 51 |

| Pump body | Cast Iron |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Gears | Cast iron Spur gears |

| Shaft | Steel |

| Shaft Seal | Oil seal or gland thread |

| Gland | Cast iron |

| Max operating temp. | 200 °C |

| Base plate | N/A |

| Pedestal with bush | N/A |

| Pulley | N/A |

| Key | En-8 |

| Hex bolts | Steel |

| Lit/min@ 400 RPM | 498 |

| operating RPM | 100 to 900 |

| 2 port | 2 |

| Working pressure | Upto 10 kgs/cm2 |

| Part | Material |

|---|---|

| Pumps series | SS 51N |

| Pump body | Cast Iron |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Gears | Cast iron Spur gears |

| Shaft | Steel |

| Shaft Seal | Oil seal or gland thread |

| Gland | Cast iron |

| Max operating temp. | 200 °C |

| Base plate | N/A |

| Pedestal with bush | N/A |

| Pulley | N/A |

| Key | En-8 |

| Hex bolts | Steel |

| Lit/min@ 400 RPM | 498 |

| operating RPM | 100 to 900 |

| 2 port | 2 |

| Working pressure | Upto 10 kgs/cm2 |

| Part | Material |

|---|---|

| Pumps series | SS 31 J |

| Pump body | WCB |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Gears | Cast iron Spur gears |

| Shaft | Steel |

| Shaft Seal | Oil seal or gland thread |

| Gland | Cast iron |

| Max operating temp. | 200 °C |

| Base plate | N/A |

| Pedestal with bush | N/A |

| Pulley | N/A |

| Key | En-8 |

| Hex bolts | Steel |

| Lit/min@ 400 RPM | 240 |

| operating RPM | 100 to 400 |

| 2 port | 2 |

| Working pressure | Upto 10 kgs/cm2 |

| Part | Material |

|---|---|

| Pumps series | SS 51 J |

| Pump body | WCB |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Gears | Cast iron Spur gears |

| Shaft | Steel |

| Shaft Seal | Oil seal or gland thread |

| Gland | Cast iron |

| Max operating temp. | 200 °C |

| Base plate | N/A |

| Pedestal with bush | N/A |

| Pulley | N/A |

| Key | En-8 |

| Hex bolts | Steel |

| Lit/min@ 400 RPM | 496 |

| operating RPM | 100 to 400 |

| 2 port | 2 |

| Working pressure | Upto 10 kgs/cm2 |

| Part | Material |

|---|---|

| Pumps series | STV 61 / BTV 61 |

| Pump body | WCB |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Gears | Cast iron Spur gears |

| Shaft | Steel |

| Shaft Seal | Oil seal or gland thread |

| Gland | Cast iron |

| Max operating temp. | 200 °C |

| Base plate | N/A |

| Pedestal with bush | Cast iron with bronze |

| Pulley | Cast iron 20” |

| Key | En-8 |

| Hex bolts | Steel |

| Lit/min@ 400 RPM | 590.8 |

| operating RPM | 100 to 400 |

| 2 port | 2 |

| Working pressure | Upto 10 kgs/cm2 |

| Part | Material |

|---|---|

| Pumps series | SS 61 |

| Pump body | WCB |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Gears | Cast iron Spur gears |

| Shaft | Steel |

| Shaft Seal | Oil seal or gland thread |

| Gland | Cast iron |

| Max operating temp. | 200 °C |

| Base plate | N/A |

| Pedestal with bush | Cast iron with bronze |

| Pulley | Cast iron 20” |

| Key | En-8 |

| Hex bolts | Steel |

| Lit/min@ 400 RPM | 590.8 |

| operating RPM | 100 to 400 |

| 2 port | 2.5” |

| Part | Material |

|---|---|

| Pumps series | ASP |

| Pump body | WCB |

| Front cover | Cast Iron |

| Back Cover | Cast Iron |

| Relief valve piston | Steel |

| Relief valve spring | Steel |

| Relief valve screw | Steel |

| Gears | Cast iron Spur gears |

| Shaft | Steel |

| Shaft Seal | Oil seal or gland thread |

| Gland | Cast iron |

| Max operating temp. | 200 °C |

| Base plate | N/A |

| Pedestal with bush | Cast iron with bronze |

| Pulley | N/A |

| Key | En-8 |

| Dowel pin | En-8 |

| Hex bolts | Steel |

| Lit/min@ 400 RPM | 600 |

| operating RPM | 100 to 400 |

| 2 port | 3” |

| Working pressure | Upto 10 kgs/cm2 |

Tokyo

Tokyo is the capital of Japan.

|

|

|

|

|

|||||||||||